Current location: Home > PRODUCTS

> Solder Products >

| view【PRODUCT - Outline】 | |||||||||||||||||||||||||||||||||

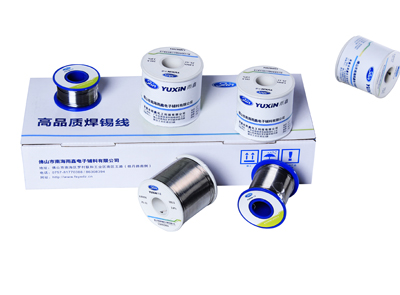

High-performance solder resists melting speed, good mobility, tin speed. Low welding spatter solder resist. Solder resist distribution, good continuity. Very little smoke and the smell of gas. Inhibit the growth of solder joint cracking, corrosion and copper alloy layer interface. Low residual, non-corrosive, high insulation resistance, no-clean solder wire. |

|||||||||||||||||||||||||||||||||

| view【Product - Features】 | |||||||||||||||||||||||||||||||||

Anaerobic continuous casting, high purity alloys. Inline resin distribution, good continuity. There are good wettability and scalability. Good weldability, welding speed, solid solder joint reliability. Welding spatter, low smoke, non-toxic health of volatile gases. Full bright spot, excellent electrical properties, very little residue after soldering. |

|||||||||||||||||||||||||||||||||

| view【Product - Technology Planning】 | |||||||||||||||||||||||||||||||||

Common specifications of solder wire

|

|||||||||||||||||||||||||||||||||

| view【Product - process parameters】 | |||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||

ABOUT US | SALSE | COOPERATION | RESOURCES | CONTACT US

Copyright:Foshan Nanhai Yu Xin Electronic Accessories Co., Ltd.

ADD:Foshan Guicheng Sea the three Road West 19-8 TEL: 86-757-86308394 FAX: 86-757-88599809

Copyright:Foshan Nanhai Yu Xin Electronic Accessories Co., Ltd.

ADD:Foshan Guicheng Sea the three Road West 19-8 TEL: 86-757-86308394 FAX: 86-757-88599809

Technical Support:wantsun

ADMIN

ADMIN